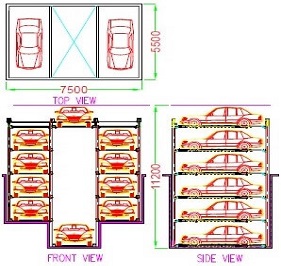

HIND TOWER CAR PARKING SYSTEM is very fast & cost-effective system. This has an elevator in the centre & on either side, there are parking spaces. The tower can be built to park up to 60 cars in a place, which can be normally used to park 3 cars only. The car has be parked at the ground level on the elevator. The elevator has the mechanism to shift the car on to either side as well as move vertically up & down. This picks up an unoccupied pallet & brings it to the ground level. After placing the car on it, the parking button had to be pressed which enables the elevator to park the car to a vacant location. To retrieve back the car, de-park button has be pressed which will bring the car to the ground level in the specified time. The system has be covered from the top & on the ground level to ensure the safety of the equipment.

All the pallet shifting mechanisms are mounted on the lift platform. At each side of the platform there are 2 geared motors with one friction wheel, each turning in opposite direction. Each pallet has 6 wheels and a bar in the middle, where the friction wheels act. The two friction wheel groups are mounted on a knock-out system driven by a central geared motor over a rack & pinion system, which can slide out on each side of the platform. The pallets have no mechanism, they need just 3 steel beams on which they can slide and 2 idle rolls to guide them.

Features

- Space effective installation makes parking up to 60 cars

- Cars possible in the space required for 3 bay

- Easy maintenance & reliable operation

- Bottom, middle & top entrance possible

- In built & stand-alone options available

- Human oriented design

- Computerized control systems

Specifications

- Car Size- Length=5050mm, Width=2000mm, Height= 1550/2000 mm [HATCHBACK/SEDAN/SUV]

- Motor- 22/30 Kw

- Lifting Capacity-1800 / 2000 Kg

- System Dimensions Required-Length=6800mm, Width=7250mm

- Speed=60/90 Meters / Min

- Operation / Control-Touch screen, PLC with Parking Guidance

- Safety Devices - Emergency Stop, Photo Sensors, Anti Fall, Guide Rail, Car Stopper & Barrier

Facts about 'Automated car parking system'

- On an average a car is driven only for 2-3 hrs. a day, the remaining time being parked, so this needs to be taken care of well

- The material used for constructing the system varies such as concrete, steel etc.

- The electricity consumption for parking and retrieving a car is only 3 KW/hr.

- The rooms that need to build to operate the system – (1) control room (2) electric room (3) pump room (4) spare storage room

- It can be a custom made to all buildings and should be incorporated during the design stage of the building itself