HIND PUZZLE PARKING SYSTEM is a parking system where a combination of lateral and vertical movement of platforms / pallets takes place to accommodate maximum number of cars within the space available. The platforms / pallets at the entry levels move only laterally. The pallets at the pit level and the top level move only vertically. The pallets at the intermediate level(s) move both vertically as well as laterally. It consists of structural columns and supports rigidly grouted to the floor with chemical anchor bolts on a levelled concrete floor. The movement of the pallets is through a single chain system & geared brake motor for both lateral & vertical movements. The geared brake motor for vertical movement is of 2.2 KW capacity and the one for lateral movement is of 0.2 KW capacity. The system can be installed in basements, or open spaces outside buildings, or even on rooftops. It is basically 2 types –

Over Grounded Puzzle Parking System

A combination of stacking and moving cars closer together.

- Compact parking on 2 to 6 levels above ground with just one driving lane.

- Various Permutation and Combinations of levels in an above the ground possible.

- Variable arrangement of 2 to 8 grids beside one another.

- Low parking and retrieval times – average of 40 to 60 seconds per car depending upon configuration.

Models

- Fully motorized, 2 level above ground & 2 to 8 grids.

- Fully motorized, 3 level above ground & 2 to 8 grids.

- Fully motorized, 4 level above ground & 2 to 8 grids.

- Fully motorized, 5 level above ground & 2 to 8 grids.

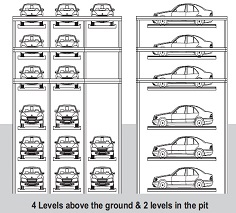

Pit Puzzle Parking System

A combination of stacking and moving cars closer together.

- Compact parking on 2 to 4 levels above ground & 1 to 2 level in below.

- Various Permutation and Combinations of levels in an underground pit and above the ground possible.

- Variable arrangement of 2 to 6 grids beside one another.

- Low parking and retrieval times – average of 40 to 60 seconds per car depending upon configuration.

Models

- Fully motorized, 2 level above ground with 1 level in pit & 2 to 8 grids.

- Fully motorized, 3 level above ground with 1 to 2 level in pit & 2 to 8 grids.

- Fully motorized, 4 level above ground with 1 to 2 level in pit & 2 to 8 grids.

- Fully motorized, 5 level above ground with 1 to 2 level in pit & 2 to 8 grids.

Features

- Independent Parking

- Indoor & outdoor installation flexibility

- Efficient use of space with Low Noise Level

- Easy & low -cost installation

- Minimal operational cost with safe operations

- Easy to drive out & not drive out

- Parking or retrieving a car takes less than 60 sec

- Lifting & lowering by Electric Motor chain drives, PLC based

- All steel structure with Corrosion resistant paint

- User friendly parking/retrieval using coded buttons identifications

Specifications

- Lifting Speed: 4.0 to 6 m/ min

- Power Requirement for vertical Lift: 1.8 KW for single pallet

- Power Requirement for vertical Lift: 3.7 KW for double pallet

- Horizontal Travel Speed: 8 M/min

- Power requirement for Horizontal Travel: 0.2 to 0.4 KW

- Power Source: 3 Phase,415 V AC 50 Hz

- Control Method: PLC

- Mechanical Safety: Car Stopper, rail guide, pallet slope, side edge frame, mechanical lock

- Electrical Safety: Phase reversal, limit switch, car guidance device emergency stopper, helical brake geared motor, Sensor

- Vehicle Type: HATCHBACK / SUV /SEDAN

- Operation: Automatic / Manuaaly

Advantages

- Compact parking on 2 to 6 levels above the ground & 1 to 2 level below ground

- Maximizing land space, construction and recurring operating costs like lighting, fire fighting, security guards by eliminating additional basements

- Efficient use of space with low noise level with low operating cost

- Achieve close to 100% volume efficiency

- Safety, security, and scratch free handling of cars

- Widest product range available in various options

- Life span-more than 25 Years

- High quality of components & electrical accessories makes long life & trouble-free maintenance

- Warranty 1 Year & AMC (Optional) thereafter by fully qualified trained engineers or as per contract